Our Green Pledge

Our mission is to continue to exceed our customers expectations with service, value creation and quality.

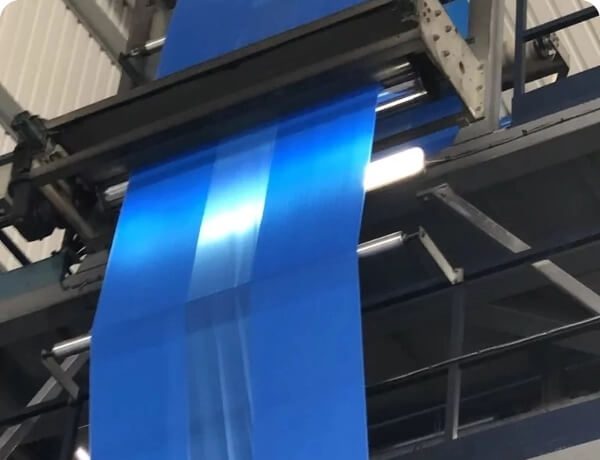

We are focused on green packaging solutions and dedicated to enhancing our product offering, that will have a positive environmental impact. We remain committed and focussed on all the key markets we serve and we will lead the way in ‘green’ film technology.

From our Biofilm material made from sugar cane that can be used for a variety of products to our exclusive Tristar material which can lower your carbon footprint by 30%. Polystar Plastics is dedicated to helping you make the change in one of the most significant aspects of all.

We are a plastics company that focuses on eco-friendly packaging solutions that will have a positive impact while additionally supporting customers with their packaging obligations and requirements. To do this, we rely on several contributing factors but are primarily concerned with 4 specialised product groups.

Going green is no longer an optional luxury of life choice; it is an essential responsibility that everyone must embrace.

Read below for more information.

Biofilm

Biofilm™ is a bio-based material made from sugar cane. It’s the process of photosynthesis as the plant grows that makes this product carbon positive.

The sugar cane actively captures CO2 from the atmosphere, while at the same time releasing oxygen – making this material not just green, but proactively green.

Biofilm™ Polythene – The Benefits

Our exclusive Biofilm™ material can be chosen as an alternative option to standard polythene for your plastic packaging across our entire product range. It offers your company the opportunity to improve your green credentials, meet legislative requirements and deliver improved environmental solutions.

PCWflex

PCWflex reuses plastic waste to create next-generation polythene

With the environment at the forefront of our thoughts, we have developed our exclusive range of PCWflex films – some of the greenest products on the market.

These materials reduce the consumption of fossil fuels (used to produce virgin grade PE), they also dramatically reduce the amount of plastic packaging going to landfill, filling our oceans, and polluting the environment. Helping to remove the issue of single-use packaging, our closed-loop manufacturing process keeps resources in use for as long as possible with a continuous round of recovery, recycling and reuse.

What does post-consumer waste mean?

Post-Consumer Waste is material that has served its intended purpose as a consumer item, and has then been separated from other material, which is to be disposed of. Post-Consumer Waste has completed its life cycle as a consumer item and can now be recycled and reused.

Why add it to polythene?

As part of its effort to tackle ongoing problems with litter and waste from single use plastic, the UK Government has announced that it intends to introduce new tax on plastic packaging that contains less than 30% recycled Post-Consumer Waste (PCW).

Supporting our environment

We have pledged our support to the amazing Surfers Against Sewage organisation – a national marine conservation charity that inspires, unites and empowers communities to take action to protect oceans, beaches, waves and wildlife.

For every tonne of PCWflex we sell, we will donate £1 to further help clean up our planet.

Compostable/Bio Degradable

Our compostable bags and film are 100% compostable meaning you can line your compost caddies with our compostable liners and place it all in the compost without having to worry about the effects on the environment.

Currently, the UK generates over 30 million tonnes of household waste every year, approximately 35% of which is garden and kitchen waste.

Compostable Plastic Bag Solution

Through continued research, development, and field trials, Polystar are proud to be one of the key independent specialist UK manufacturers, which can produce this next generation product which is a 100% compostable.

Advantages of Compostable Plastic Bags

The main advantage is that our bio-plastic does not contain any starch. Starch is sensitive to moisture so if you left standard compostable bags in damp conditions (e.g. inside the bin or under the sink), they can begin to prematurely degrade. This can lead to your waste ending up on the floor and not in the composter.

Why Choose Compostable Plastic Bags?

Our technology that makes our compostable bags is a blend of co-polyester and PLA (sugar cane, which is a renewable resource).

The benefits of this compostable solution are:

- Outstanding mechanical properties and perform in a way similar to regular polythene bags and film

- Very high content of natural resource raw material

- Superior breathability

- Excellent ink adhesion for professional print quality

Our compostable plastic bags all adhere to the following specifications:

- Are manufactured in the UK at our own facility.

- EN13432 Accredited

- Can be made in any size although the most common are 7 or 10 litre caddy liner, 25 litre bag and 80 litre sack.

- Available on a roll or loose in boxes

- Fully printable with your logo and details

An environmentally friendly alternatives to standard polythene film and bags, our degradable film are designed to break down naturally making it easier to dispose of and eliminating the need for to recycle or take up space in landfill sites.

Over time, all standard plastic will eventually biodegrade, but this will take many decades. Our Oxy Biodegradable range means you can bin your waste, without thinking about harm caused to the environment.

We have partnered with a leading plastic technologist to develop a biodegradable plastics material that not only fully degrades to minimise the impact from landfill, but is also 100% recyclable.

The product is available in conjunction with any of our materials.

Our biodegradable packaging’s key features include the following:

- Full recyclable

- Only a small premium

- Equivalent strength and weight to normal plastic

- Leak proof

- Degrades on land or sea

For large local authority clients, we have various initiatives which Polystar can offer such as free tree planting. This helps the countryside, increases our biodiversity, and raises significant awareness in local communities from the PR generated.

Biofilm™ and TRISTAR™ can be used across our full plastic packaging product range including:

Collation Shrink Film

Secure your products using low-density polyethylene (LDPE) collation shrink film for a cost-effective, efficient, versatile packaging solution.

Pallet Covers and Top Sheets

Pallet covers are the most cost-effective way of ensuring your products remain dry and dust-free.

Mailing Bags and Film

Our plastic mailing bags provide the perfect mailing film solution, so your literature reaches its customers in quality condition.

Food Grade Polythene Bags and Dolav Liners

Polystar manufactures a wide range of specially designed bespoke food-safe plastic food liners. at any scale. You can also directly purchase dolav liners here.

+44 (0) 2380 232153

+44 (0) 2380 232153